Product Description

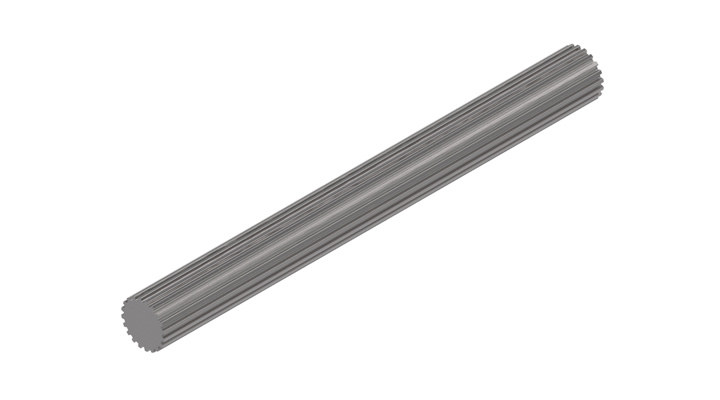

Wide Angle Pto Adaptor Cardan Spline Shaft Yoke Tube Torque Limiter Universal Joint cross Cover Agricultural Machinery Tractor Parts Pto Drive Shaft

Product Description

A PTO shaft (Power Take-Off shaft) is a mechanical component used to transfer power from a tractor or other power source to an attached implement such as a mower, tiller, or baler. The PTO shaft is typically located at the rear of the tractor and is powered by the tractor’s engine through the transmission.

The PTO shaft is designed to provide a rotating power source to the implement, allowing it to perform its intended function. The implement is connected to the PTO shaft using a universal joint, which allows for movement between the tractor and the implement while still maintaining a constant power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

| SHIELD S | SHIELD W |

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.What’re your main products?

we currently product Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gear pump and motor.You can check the specifications for above product on our website and you can email us to recommend needed product per your specification too.

2.What’s the lead time for a regular order?

Generally speaking, our regular standard product will need 30-45days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

3.What’s your warranty terms?

One year.

4.Can you send me a price list?

For all of our product, they are customized based on different requirements like length, ratio,voltage,and power etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

5.What’s the payment term?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

6.How to deliver the goods to us?

Usually we will ship the goods to you by sea.

PTO Drive Shaft Parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Agricultural Spare Part, Agricultural Spare Part |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery,Farm Tractor, Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery, Farm Tractor |

| Material: | Carbon Steel, 45cr Steel, Carbon Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

What materials are commonly used in the construction of spline shafts?

Various materials are commonly used in the construction of spline shafts, depending on the specific application requirements. Here’s a list of commonly used materials:

1. Steel:

Steel is one of the most widely used materials for spline shafts. Different grades of steel, such as carbon steel, alloy steel, or stainless steel, can be employed based on factors like strength, hardness, and corrosion resistance. Steel offers excellent mechanical properties, including high strength, durability, and wear resistance, making it suitable for a broad range of applications.

2. Alloy Steel:

Alloy steel is a type of steel that contains additional alloying elements, such as chromium, molybdenum, or nickel. These alloying elements enhance the mechanical properties of the steel, providing improved strength, toughness, and wear resistance. Alloy steel spline shafts are commonly used in applications that require high torque capacity, durability, and resistance to fatigue.

3. Stainless Steel:

Stainless steel is known for its corrosion resistance properties, making it suitable for applications where the spline shaft is exposed to moisture or corrosive environments. Stainless steel spline shafts are commonly used in industries such as food processing, chemical processing, marine, and medical equipment.

4. Aluminum:

Aluminum is a lightweight material with good strength-to-weight ratio. It is often used in applications where weight reduction is a priority, such as automotive and aerospace industries. Aluminum spline shafts can provide advantages such as decreased rotating mass and improved fuel efficiency.

5. Titanium:

Titanium is a strong and lightweight material with excellent corrosion resistance. It is commonly used in high-performance applications where weight reduction, strength, and corrosion resistance are critical factors. Titanium spline shafts find applications in aerospace, motorsports, and high-end industrial equipment.

6. Brass:

Brass is an alloy of copper and zinc, offering good machinability and corrosion resistance. It is often used in applications that require electrical conductivity or a non-magnetic property. Brass spline shafts can be found in industries such as electronics, telecommunications, and instrumentation.

7. Plastics and Composite Materials:

In certain applications where weight reduction, corrosion resistance, or noise reduction is important, plastics or composite materials can be used for spline shafts. Materials such as nylon, acetal, or fiber-reinforced composites can provide specific advantages in terms of weight, low friction, and resistance to chemicals.

It’s important to note that material selection for spline shafts depends on factors such as load requirements, environmental conditions, operating temperatures, and cost considerations. Engineers and designers evaluate these factors to determine the most suitable material for a given application.

How does a spline shaft differ from other types of shafts?

A spline shaft differs from other types of shafts in several ways. Here’s a detailed explanation:

1. Spline Structure:

A spline shaft features a series of ridges or teeth (splines) that are machined onto its surface. These splines create a precise and controlled interface with mating components, allowing for torque transmission and relative movement. In contrast, other types of shafts, such as plain shafts or keyed shafts, do not have the splines and rely on different mechanisms for torque transmission.

2. Torque Transmission and Relative Movement:

Unlike plain shafts or keyed shafts, which transmit torque through a frictional or mechanical connection, spline shafts allow for both torque transmission and relative movement between the shaft and mating components. The splines on the shaft engage with corresponding splines on the mating component, creating an interlock that transfers rotational force while accommodating axial or radial displacement. This feature provides flexibility and is particularly useful in applications where misalignment or relative movement needs to be accommodated.

3. Load Distribution:

One of the advantages of spline shafts is their ability to distribute loads over a larger surface area. The multiple contact points created by the splines help distribute the applied load evenly along the shaft’s length. This load distribution minimizes stress concentrations and reduces the risk of premature wear or failure. In contrast, other types of shafts may rely on a single keyway or frictional contact, which can result in higher stress concentrations and limited load distribution.

4. Design Flexibility:

Spline shafts offer greater design flexibility compared to other types of shafts. The number, size, and shape of the splines can be customized to meet specific design requirements. This allows for optimization of torque transmission, load-bearing capacity, and relative movement characteristics based on the application’s needs. Other types of shafts may have more standardized designs and limited customization options.

5. Application Variability:

Spline shafts find widespread use in various industries and applications where torque transmission, relative movement, and load distribution are crucial. They are commonly employed in gearboxes, power transmission systems, steering mechanisms, and other rotational systems. Other types of shafts, such as plain shafts or keyed shafts, may be more suitable for applications that require simpler torque transmission without the need for relative movement.

6. Installation and Maintenance:

When compared to other types of shafts, spline shafts may require more precise machining and alignment during installation. The mating components must be accurately matched to ensure proper engagement and torque transfer. Additionally, spline shafts may require periodic inspection and maintenance to ensure the integrity of the splines and optimal performance.

In summary, spline shafts differ from other types of shafts due to their spline structure, ability to accommodate relative movement, load distribution capability, design flexibility, application variability, and specific installation and maintenance requirements. These characteristics make spline shafts well-suited for applications that demand precise torque transmission, flexibility, and load distribution.

editor by CX 2024-04-25

in Toronto Canada sales price shop near me near me shop factory supplier Agricultural Machinery Rice Thresher Shelling Machine for Sell manufacturer best Cost Custom Cheap wholesaler

In 2000, EPG took the direct in attaining ISO14001 environment administration certificate and thereafter handed the inspection of clean creation and recycling financial system, profitable the title of “Zhejiang Environmentally friendly Organization”. Our solution range consists of all sorts of helical equipment, spur gear, bevel equipment, equipment rack, worm gear, sprockets,chains, bearings. If you require any info or samples, remember to contact us and you will have our soon reply. agricultural EPTTry rice thresher shelling EPTT for offer

description:

rice thresher

Product No.: DQTL125

manufacturing: 4500-5000KG

matcher EPTT: 11KW electrical moter or 15hp,18hp diesel engine

dimension:2400*2570*1530mm

releated merchandise:

EPTT and shipping :

FAQ:

Q: What is the warranty of your agricultural EPTTs?

A: 1 year ensure for EPTT EPTT

Q: How EPTT is your shipping and delivery time ?

A:Typically it normally takes ten-35 daEPTTto produce after getting your payment

Q: What is the payment time period ?

A:T/TWestorn unionEPT assurance and so on

Q: Is OEM or ODM support suitable ?

A:EPTT services is available,in accordance to customer’s regional submitted problem

organization profile:

EPTTYU business mainly supply Farm tractors, Merge harvesters and related EPTTlements, as effectively as their spare parts.

Also we supply OEM provider for Distinct brand names tractors PTO Driving shafts, EPTs, Rotary blades.

If you could not find the goods on our internet site, Welcome to send us drawing or sample, we could customized as your wants.

in Samut Sakhon Thailand sales price shop near me near me shop factory supplier Agricultural Machinery Farm Tractor Pto Finishing Mower manufacturer best Cost Custom Cheap wholesaler

EPG is a skilled manufacturer and exporter that is involved with the style, improvement and creation. Obtaining amassed precious knowledge in cooperating with foreign buyers, EPG was awarded with “well-known item of Zhejiang Province” and “renowned model of Zhejiang Province”.

EPTT EPTTry Farm Tractor Pto Finishing Mower

Product Information: one.EPTT: By PTO SEPTFT two.Graphite EPTT is made of casting iron three.The suspension plate shape is made by laser chopping,molding location 4.With adjustable rear roller, the mowing heigEPTT can be altered easily 5.Aspect safety plates are added onto the rear deflection 6. straigEPTT blades for grass. (Optional for consumers.) 7.The blades are unEPTThot working and EPTT testing eight.With entrance security, to avoid splashing 9. Use powEPTTpainting 10.Labels are:water evidence, moist evidence, mould proof, anti-ultraviolet radiation

Ensure amp Guarantee: 1.Guarantee time:14months,EPTTer than any other EPTT suppliers. two.With CE CERTIFICATES. three.All of your purchased EPTTs will be examined to ensure the quality just before cargo. 4.We will provide you with the test reports together with the container or sample packages. 5.Even the packages,all of them are certain for customs verify or inspections.

HangEPT EPTT. AGRO Sector (B.T.A), as one of the major makers in the generation of agricultural equipments, is located in TiHangEPT District, HangEPT, EPTTngsu, EPTT, with great area, practical transportation and enhance resources.

B.T.A’s motto is quottending to the specifics other individuals can ‘t quot, and it is dedicated to generating the best brand in the higher-conclude agricultural EPTTry. In line with the philosophy of quottaking the initiative to participate in market competitiveness quot, B.T.A spares no hard work to style and deveXiHu (West EPT) Dis.Hu (West EPT) Dis. the most expert and the most advanced new kinds of agricultural EPTTry merchandise.

B.T.A has expert laser chopping EPTTs, fully computerized CNC bending EPTTs, stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd welding jigs and computerized spraying manufacturing line and other EPTd creation equipment, as effectively as outstanding EPT investigation and deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment staff. It strictly follows European amp American Style and Use StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd and adopts an EPTd administration system and rigid top quality management. It not only presents stringent item efficiency assessment according to the field examination specification and passed the EPTT, but also continually increases and upgrades goods right after person comments. B.T.A is properly acknowledged with its superior design and style, prosperous types and trustworthy high quality, it is eEPTTly regarded in the United States, Germany, Netherlands, Belgium, Australia and other nations around the world.

B.T.A is mainly engaged in the investigation and deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment, manufacturing and income of numerous kinds of agricultural and XiHu (West EPT) Dis.Hu (West EPT) Dis.den EPTTry. Our major goods are divided into our categories: farm EPTTry, XiHu (West EPT) Dis.Hu (West EPT) Dis.den EPTTry, forestry EPTTry and road EPTTry. Some of our effectively acknowledged goods incEPTT 3 point linkage rotary tiller, finishing mower, flail mower, verge flail mower, rotary slasher, wooden chipper, trailer, spare elements and Japanese tractor equipment, which are exported to over twenty nations around the world.

In the EPT, B.T.A will even more enhance the construction of eXiHu (West EPT) Dis.sting products according to the specifications and characteristics of farmers, fulfill the wants of the global marketplace and establish the best after-revenue service technique.

one.Delivery time:35 functioning days

2.From confirming the orEPTTto shipment,our soon after-sale provider will update the photos to you.

Q1. What are your phrases of EPTT?

A: EPTTly, we pack our merchandise in bulks or wood box, suitable for shipping container.

Q2. What is your conditions of payment?

A: T/T 30% as deposit, and 70% prior to delivery. We are going to display you the images of the merchandise and deals just before you pay out the stability.

Q3. What are your conditions of shipping and delivery?

A: EXW, FOB, CFR, CIF.

This fall. How about your shipping time?

A: EPTTly, it will get 10 to 15 times soon after getting your EPT payment. The distinct shipping and delivery time relies upon

on the products and the amount of your order.

Q5. Can you create according to the samples?

A: Of course, we can generate by your samples or complex drawings.

Q6. What is your sample coverage?

A: We can source the sample if we have prepared parts in stock.

Q7. Do you examination all your items just before supply?

A: Yes, we have 100% check just before shipping and delivery.

Q8: How do you make our business EPTT-phrase and very good partnership?

A1:We keep outstanding good quality, considerate soon after-income service and aggressive price to guarantee our customers’ gain

A2:We respect each client as our friend and we sincerely do business and make close friends with them, no subject exactly where they come from

Best supplier made in China – replacement parts – PTO shaft manufacturer & factory Exporting brush hog pto Agricultural Farm Machinery Wheel Tractor with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing unit in China with 5 distinct branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto travel shaft yoke It kubota l2501 pto shaft is 52105981ac our ford 8n pto shaft seal intention toyota yaris travel shaft to drive shaft u joint press offer rav4 push shaft replacement cost a pto shaft couplings extensive volvo travel shaft selection taking away pto shaft from tractor of top quality goods at reasonably priced charges, offer the best service for customers pleased and add to our continued improvement. Our firm has sound economic power, builds up a technician team contingent with higher quality, possesses the production assembly line of technicalization in China and excellent technique checking on product good quality and operates marketing and advertising networks throughout the place.

Product Description

one, binheng provides a broad variety of tractors from sixteen HP to 225 HP

2, binheng 20 ~ 55HP tractor EPA 4 accepted

3, binheng 16 ~ 45HP tractor EEC/E-MARK accredited provide COC report

4, All OECD approved

Obtainable implements:

Entrance stop loader, hydraulic backhoe entrance, plough, rotary cultivator, seed drill, Excavator, one shaft or hydraulic dump trailer, PTO shaft driving water pump Or generator, chipper, ditching machine, mower, snow blower

Xihu (West Lake) Dis.ng gives a broad option of characteristics across the full selection of tractors. Energy steering, 2WD/Four wheel drive alternatives, Cabin, Roll More than Protection bar, canopy, Decision of tyres i. e turf tyres, industrial tyres, High lug tyres are available across the variety.

Xihu (West Lake) Dis.ng owns the selection of attributes, helps make it one the most appropriate tractors for a host of programs. The tractors are suited for backyard garden applications, pastime applications, soaked & dry land programs, transportation in basic or hilly locations.

binheng’s utility of the tractor is further increased by the offering of a complete assortment of matching implements like loaders, backhoe, post gap digger, scraper, leveler, rotavator, tiller, cultivator, plough, harrows, wood chipper, mower, snow Blower and so on.

binhengoffers the backed up by qualified manpower, spares parts & provider supports at the closest distribution stage in all the countries.

The binheng model of tractors are getting constructed to give a absolutely satisfying knowledge to the clients.