Product Description

Product Description

Product Parameters

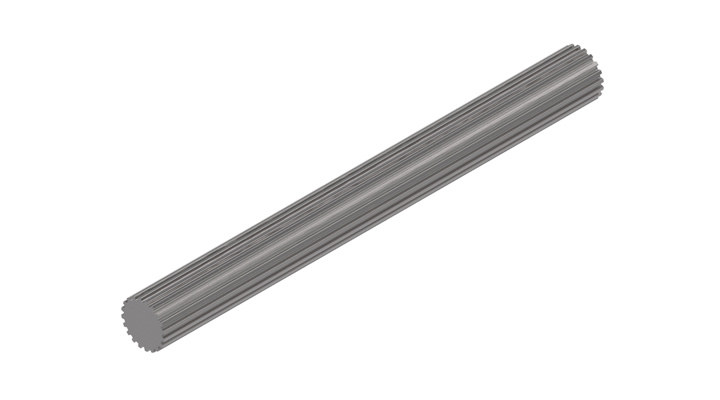

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

Can spline shafts be repaired or maintained when necessary?

Yes, spline shafts can be repaired and maintained when necessary to ensure their continued functionality and performance. Here are some ways spline shafts can be repaired and maintained:

1. Inspection and Assessment:

When an issue is suspected with a spline shaft, the first step is to conduct a thorough inspection. This involves examining the shaft for any signs of wear, damage, or misalignment. Special attention is given to the spline teeth, which may show signs of wear or deformation. Through inspection and assessment, the extent of the repair or maintenance required can be determined.

2. Spline Tooth Repair:

If the spline teeth are damaged or worn, they can be repaired or replaced. Repair methods may include re-machining the teeth to restore their original profile, filling and reshaping the worn areas using specialized welding techniques, or replacing the damaged section of the spline shaft. The specific repair method depends on the severity of the damage and the material of the spline shaft.

3. Lubrication and Cleaning:

Regular lubrication and cleaning are essential for maintaining spline shafts. Lubricants help reduce friction and wear between the mating surfaces, while cleaning removes contaminants that can affect the spline’s engagement. During maintenance, old lubricants are removed, and fresh lubricants are applied to ensure smooth operation and prevent premature failure.

4. Surface Treatment:

If the spline shaft undergoes wear or corrosion, surface treatment can be applied to restore its condition. This may involve applying coatings or treatments to enhance the hardness, wear resistance, or corrosion resistance of the spline shaft. Surface treatments can improve the longevity and performance of the spline shaft, reducing the need for frequent repairs.

5. Balancing and Alignment:

If a spline shaft is experiencing vibration or misalignment issues, it may require balancing or realignment. Balancing involves redistributing mass along the shaft to minimize vibrations, while alignment ensures proper mating and engagement with other components. Balancing and alignment procedures help optimize the performance and longevity of the spline shaft.

6. Replacement:

In cases where the spline shaft is severely damaged or worn beyond repair, replacement may be necessary. Replacement spline shafts can be sourced from manufacturers or specialized suppliers who can provide shafts that meet the required specifications and tolerances.

It’s important to note that the repair and maintenance of spline shafts should be carried out by qualified professionals with expertise in precision machining and mechanical systems. They have the knowledge and tools to properly assess, repair, or replace spline shafts, ensuring the integrity and functionality of the system in which they are used.

By implementing regular maintenance and timely repairs, spline shafts can be kept in optimal condition, extending their lifespan and maintaining their performance in various mechanical applications.

In which industries are spline shafts typically used?

Spline shafts find applications in a wide range of industries where torque transmission, relative movement, and load distribution are critical. Here’s a detailed explanation:

1. Automotive Industry:

The automotive industry extensively uses spline shafts in various components and systems. They are found in transmissions, drivelines, steering systems, differentials, and axle assemblies. Spline shafts enable the transmission of torque, accommodate relative movement, and ensure efficient power transfer in vehicles.

2. Aerospace and Defense Industry:

Spline shafts are essential in the aerospace and defense industry. They are used in aircraft landing gear systems, actuation mechanisms, missile guidance systems, engine components, and rotor assemblies. The aerospace and defense sector relies on spline shafts for precise torque transfer, relative movement accommodation, and critical control mechanisms.

3. Industrial Machinery and Equipment:

Spline shafts are widely employed in industrial machinery and equipment. They are used in gearboxes, machine tools, pumps, compressors, conveyors, printing machinery, and packaging equipment. Spline shafts enable torque transmission, accommodate misalignments and vibrations, and ensure accurate movement and synchronization of machine components.

4. Agriculture and Farming:

The agriculture and farming industry extensively uses spline shafts in equipment such as tractors, harvesters, and agricultural implements. Spline shafts are found in power take-off (PTO) units, transmission systems, hydraulic mechanisms, and steering systems. They enable torque transfer, accommodate relative movement, and provide flexibility in agricultural machinery.

5. Construction and Mining:

In the construction and mining industries, spline shafts are used in equipment such as excavators, loaders, bulldozers, and drilling rigs. They are found in hydraulic systems, power transmission systems, and articulated mechanisms. Spline shafts facilitate torque transmission, accommodate misalignments, and enable efficient power transfer in heavy-duty machinery.

6. Marine and Offshore:

Spline shafts have applications in the marine and offshore industry. They are used in propulsion systems, thrusters, rudders, winches, and marine pumps. Spline shafts enable torque transmission in marine vessels and offshore equipment, accommodating axial and radial movement, and ensuring reliable power transfer.

7. Energy and Power Generation:

Spline shafts are utilized in the energy and power generation sector. They are found in turbines, generators, compressors, and other rotating equipment. Spline shafts enable torque transmission and accommodate relative movement in power generation systems, ensuring efficient and reliable operation.

8. Rail and Transportation:

Spline shafts are employed in the rail and transportation industry. They are found in locomotives, railcar systems, and suspension mechanisms. Spline shafts enable torque transfer, accommodate movement and vibrations, and ensure precise control in rail and transportation applications.

These are just a few examples of the industries where spline shafts are typically used. Their versatility, torque transmission capabilities, and ability to accommodate relative movement make them vital components in various sectors that rely on efficient power transfer, flexibility, and precise control.

editor by CX 2024-04-10

China Hot selling Long Stainless Steel Straight Spline Drive Gear Shaft for Rice Transplanter

Product Description

Product Description

Product Parameters

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do spline shafts handle variations in torque and rotational force?

Spline shafts are designed to handle variations in torque and rotational force in mechanical systems. Here’s a detailed explanation:

1. Interlocking Splines:

Spline shafts have a series of interlocking splines along their length. These splines engage with corresponding splines on the mating component, such as gears or couplings. The interlocking design ensures a secure and robust connection, capable of transmitting torque and rotational force.

2. Load Distribution:

When torque is applied to a spline shaft, the load is distributed across the entire engagement surface of the splines. This helps to minimize stress concentrations and prevents localized wear or failure. The load distribution capability of spline shafts allows them to handle variations in torque and rotational force effectively.

3. Material Selection:

Spline shafts are typically made from materials with high strength and durability, such as alloy steels. The material selection is crucial in handling variations in torque and rotational force. It ensures that the spline shaft can withstand the applied loads without deformation or failure.

4. Spline Profile:

The design of the spline profile also contributes to the handling of torque variations. The spline profile determines the contact area and the distribution of forces along the splines. By optimizing the spline profile, manufacturers can enhance the load-carrying capacity and improve the ability of the spline shaft to handle variations in torque.

5. Surface Finish and Lubrication:

Proper surface finish and lubrication play a crucial role in the performance of spline shafts. A smooth surface finish reduces friction and wear, while suitable lubrication minimizes heat generation and ensures smooth operation. These factors help in handling variations in torque and rotational force by reducing the impact of friction and wear on the spline engagement.

6. Design Considerations:

Engineers take several design considerations into account to ensure spline shafts can handle variations in torque and rotational force. These considerations include appropriate spline dimensions, tooth profile geometry, spline fit tolerance, and the selection of mating components. By carefully designing the spline shaft and its mating components, engineers can optimize the system’s performance and reliability.

7. Overload Protection:

In some applications, spline shafts may be equipped with overload protection mechanisms. These mechanisms, such as shear pins or torque limiters, are designed to disconnect the drive temporarily or slip when the torque exceeds a certain threshold. This protects the spline shaft and other components from damage due to excessive torque.

Overall, spline shafts handle variations in torque and rotational force through their interlocking splines, load distribution capability, appropriate material selection, optimized spline profiles, surface finish, lubrication, design considerations, and, in some cases, overload protection mechanisms. These features ensure efficient torque transmission and enable spline shafts to withstand the demands of various mechanical systems.

Can spline shafts be applied in aerospace and aviation equipment?

Yes, spline shafts are commonly applied in aerospace and aviation equipment due to their ability to transmit torque and provide precise rotational motion. Here’s how spline shafts are used in the aerospace and aviation industry:

1. Aircraft Engines:

Spline shafts are utilized in aircraft engines for various purposes. They can be found in the engine’s accessory gearbox, where they transmit torque from the engine to drive auxiliary components such as fuel pumps, hydraulic pumps, generators, and engine starters. Spline shafts are also present in the engine’s variable geometry systems, which control the position of components like variable stator vanes or variable inlet guide vanes.

2. Flight Control Systems:

Spline shafts play a vital role in aircraft flight control systems. They are employed in the actuators and control mechanisms that operate the flaps, ailerons, elevators, rudders, and other control surfaces. Spline shafts enable precise and efficient transfer of control inputs from the cockpit to the respective control surfaces, contributing to the maneuverability and stability of the aircraft.

3. Landing Gear:

Spline shafts are used in the landing gear systems of aircraft. They can be found in components such as the landing gear actuator, which extends and retracts the landing gear, and the steering mechanism that controls the nose wheel. Spline shafts in landing gear systems need to withstand high loads, provide reliable operation, and ensure precise movement for safe and smooth landings and takeoffs.

4. Helicopter Rotors:

Helicopters rely on spline shafts in the main rotor assembly. The main rotor shaft, which transfers power from the helicopter’s engine to the rotor blades, often incorporates splines to ensure a secure connection and efficient torque transmission. Spline shafts are critical for maintaining stable and precise rotation of the rotor blades, allowing for controlled lift and maneuverability.

5. Auxiliary Systems:

Spline shafts are also applied in various auxiliary systems in aerospace and aviation equipment. These include systems such as power transmission for onboard generators, environmental control systems, fuel control systems, and hydraulic systems. Spline shafts in these applications contribute to the reliable operation and efficient functioning of the auxiliary equipment.

In aerospace and aviation applications, spline shafts are designed to meet stringent requirements for strength, durability, precision, and weight reduction. They are often made from high-strength materials such as titanium or alloy steel to withstand the demanding operating conditions and weight constraints of aircraft. Additionally, advanced manufacturing techniques are employed to ensure the dimensional accuracy and quality of spline shafts for critical aerospace applications.

The use of spline shafts in aerospace and aviation equipment enables precise control, efficient power transmission, and reliable operation, contributing to the safety, performance, and functionality of aircraft and related systems.

In which industries are spline shafts typically used?

Spline shafts find applications in a wide range of industries where torque transmission, relative movement, and load distribution are critical. Here’s a detailed explanation:

1. Automotive Industry:

The automotive industry extensively uses spline shafts in various components and systems. They are found in transmissions, drivelines, steering systems, differentials, and axle assemblies. Spline shafts enable the transmission of torque, accommodate relative movement, and ensure efficient power transfer in vehicles.

2. Aerospace and Defense Industry:

Spline shafts are essential in the aerospace and defense industry. They are used in aircraft landing gear systems, actuation mechanisms, missile guidance systems, engine components, and rotor assemblies. The aerospace and defense sector relies on spline shafts for precise torque transfer, relative movement accommodation, and critical control mechanisms.

3. Industrial Machinery and Equipment:

Spline shafts are widely employed in industrial machinery and equipment. They are used in gearboxes, machine tools, pumps, compressors, conveyors, printing machinery, and packaging equipment. Spline shafts enable torque transmission, accommodate misalignments and vibrations, and ensure accurate movement and synchronization of machine components.

4. Agriculture and Farming:

The agriculture and farming industry extensively uses spline shafts in equipment such as tractors, harvesters, and agricultural implements. Spline shafts are found in power take-off (PTO) units, transmission systems, hydraulic mechanisms, and steering systems. They enable torque transfer, accommodate relative movement, and provide flexibility in agricultural machinery.

5. Construction and Mining:

In the construction and mining industries, spline shafts are used in equipment such as excavators, loaders, bulldozers, and drilling rigs. They are found in hydraulic systems, power transmission systems, and articulated mechanisms. Spline shafts facilitate torque transmission, accommodate misalignments, and enable efficient power transfer in heavy-duty machinery.

6. Marine and Offshore:

Spline shafts have applications in the marine and offshore industry. They are used in propulsion systems, thrusters, rudders, winches, and marine pumps. Spline shafts enable torque transmission in marine vessels and offshore equipment, accommodating axial and radial movement, and ensuring reliable power transfer.

7. Energy and Power Generation:

Spline shafts are utilized in the energy and power generation sector. They are found in turbines, generators, compressors, and other rotating equipment. Spline shafts enable torque transmission and accommodate relative movement in power generation systems, ensuring efficient and reliable operation.

8. Rail and Transportation:

Spline shafts are employed in the rail and transportation industry. They are found in locomotives, railcar systems, and suspension mechanisms. Spline shafts enable torque transfer, accommodate movement and vibrations, and ensure precise control in rail and transportation applications.

These are just a few examples of the industries where spline shafts are typically used. Their versatility, torque transmission capabilities, and ability to accommodate relative movement make them vital components in various sectors that rely on efficient power transfer, flexibility, and precise control.

editor by CX 2023-12-22

China Best Sales Direct Transplanter Manufacturers with Straight Spline Transmission Gear Shaft carbon fiber drive shaft

Product Description

Product Description

Product Parameters

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to Calculate Stiffness, Centering Force, Wear and Fatigue Failure of Spline Couplings

There are various types of spline couplings. These couplings have several important properties. These properties are: Stiffness, Involute splines, Misalignment, Wear and fatigue failure. To understand how these characteristics relate to spline couplings, read this article. It will give you the necessary knowledge to determine which type of coupling best suits your needs. Keeping in mind that spline couplings are usually spherical in shape, they are made of steel.

Involute splines

An effective side interference condition minimizes gear misalignment. When two splines are coupled with no spline misalignment, the maximum tensile root stress shifts to the left by five mm. A linear lead variation, which results from multiple connections along the length of the spline contact, increases the effective clearance or interference by a given percentage. This type of misalignment is undesirable for coupling high-speed equipment.

Involute splines are often used in gearboxes. These splines transmit high torque, and are better able to distribute load among multiple teeth throughout the coupling circumference. The involute profile and lead errors are related to the spacing between spline teeth and keyways. For coupling applications, industry practices use splines with 25 to fifty-percent of spline teeth engaged. This load distribution is more uniform than that of conventional single-key couplings.

To determine the optimal tooth engagement for an involved spline coupling, Xiangzhen Xue and colleagues used a computer model to simulate the stress applied to the splines. The results from this study showed that a “permissible” Ruiz parameter should be used in coupling. By predicting the amount of wear and tear on a crowned spline, the researchers could accurately predict how much damage the components will sustain during the coupling process.

There are several ways to determine the optimal pressure angle for an involute spline. Involute splines are commonly measured using a pressure angle of 30 degrees. Similar to gears, involute splines are typically tested through a measurement over pins. This involves inserting specific-sized wires between gear teeth and measuring the distance between them. This method can tell whether the gear has a proper tooth profile.

The spline system shown in Figure 1 illustrates a vibration model. This simulation allows the user to understand how involute splines are used in coupling. The vibration model shows four concentrated mass blocks that represent the prime mover, the internal spline, and the load. It is important to note that the meshing deformation function represents the forces acting on these three components.

Stiffness of coupling

The calculation of stiffness of a spline coupling involves the measurement of its tooth engagement. In the following, we analyze the stiffness of a spline coupling with various types of teeth using two different methods. Direct inversion and blockwise inversion both reduce CPU time for stiffness calculation. However, they require evaluation submatrices. Here, we discuss the differences between these two methods.

The analytical model for spline couplings is derived in the second section. In the third section, the calculation process is explained in detail. We then validate this model against the FE method. Finally, we discuss the influence of stiffness nonlinearity on the rotor dynamics. Finally, we discuss the advantages and disadvantages of each method. We present a simple yet effective method for estimating the lateral stiffness of spline couplings.

The numerical calculation of the spline coupling is based on the semi-analytical spline load distribution model. This method involves refined contact grids and updating the compliance matrix at each iteration. Hence, it consumes significant computational time. Further, it is difficult to apply this method to the dynamic analysis of a rotor. This method has its own limitations and should be used only when the spline coupling is fully investigated.

The meshing force is the force generated by a misaligned spline coupling. It is related to the spline thickness and the transmitting torque of the rotor. The meshing force is also related to the dynamic vibration displacement. The result obtained from the meshing force analysis is given in Figures 7, 8, and 9.

The analysis presented in this paper aims to investigate the stiffness of spline couplings with a misaligned spline. Although the results of previous studies were accurate, some issues remained. For example, the misalignment of the spline may cause contact damages. The aim of this article is to investigate the problems associated with misaligned spline couplings and propose an analytical approach for estimating the contact pressure in a spline connection. We also compare our results to those obtained by pure numerical approaches.

Misalignment

To determine the centering force, the effective pressure angle must be known. Using the effective pressure angle, the centering force is calculated based on the maximum axial and radial loads and updated Dudley misalignment factors. The centering force is the maximum axial force that can be transmitted by friction. Several published misalignment factors are also included in the calculation. A new method is presented in this paper that considers the cam effect in the normal force.

In this new method, the stiffness along the spline joint can be integrated to obtain a global stiffness that is applicable to torsional vibration analysis. The stiffness of bearings can also be calculated at given levels of misalignment, allowing for accurate estimation of bearing dimensions. It is advisable to check the stiffness of bearings at all times to ensure that they are properly sized and aligned.

A misalignment in a spline coupling can result in wear or even failure. This is caused by an incorrectly aligned pitch profile. This problem is often overlooked, as the teeth are in contact throughout the involute profile. This causes the load to not be evenly distributed along the contact line. Consequently, it is important to consider the effect of misalignment on the contact force on the teeth of the spline coupling.

The centre of the male spline in Figure 2 is superposed on the female spline. The alignment meshing distances are also identical. Hence, the meshing force curves will change according to the dynamic vibration displacement. It is necessary to know the parameters of a spline coupling before implementing it. In this paper, the model for misalignment is presented for spline couplings and the related parameters.

Using a self-made spline coupling test rig, the effects of misalignment on a spline coupling are studied. In contrast to the typical spline coupling, misalignment in a spline coupling causes fretting wear at a specific position on the tooth surface. This is a leading cause of failure in these types of couplings.

Wear and fatigue failure

The failure of a spline coupling due to wear and fatigue is determined by the first occurrence of tooth wear and shaft misalignment. Standard design methods do not account for wear damage and assess the fatigue life with big approximations. Experimental investigations have been conducted to assess wear and fatigue damage in spline couplings. The tests were conducted on a dedicated test rig and special device connected to a standard fatigue machine. The working parameters such as torque, misalignment angle, and axial distance have been varied in order to measure fatigue damage. Over dimensioning has also been assessed.

During fatigue and wear, mechanical sliding takes place between the external and internal splines and results in catastrophic failure. The lack of literature on the wear and fatigue of spline couplings in aero-engines may be due to the lack of data on the coupling’s application. Wear and fatigue failure in splines depends on a number of factors, including the material pair, geometry, and lubrication conditions.

The analysis of spline couplings shows that over-dimensioning is common and leads to different damages in the system. Some of the major damages are wear, fretting, corrosion, and teeth fatigue. Noise problems have also been observed in industrial settings. However, it is difficult to evaluate the contact behavior of spline couplings, and numerical simulations are often hampered by the use of specific codes and the boundary element method.

The failure of a spline gear coupling was caused by fatigue, and the fracture initiated at the bottom corner radius of the keyway. The keyway and splines had been overloaded beyond their yield strength, and significant yielding was observed in the spline gear teeth. A fracture ring of non-standard alloy steel exhibited a sharp corner radius, which was a significant stress raiser.

Several components were studied to determine their life span. These components include the spline shaft, the sealing bolt, and the graphite ring. Each of these components has its own set of design parameters. However, there are similarities in the distributions of these components. Wear and fatigue failure of spline couplings can be attributed to a combination of the three factors. A failure mode is often defined as a non-linear distribution of stresses and strains.

editor by CX 2023-06-02

China Precision Long Stainless Steel Straight Spline Drive Gear Shaft drive shaft electric motor

Product Description

Precision cnc machining lengthy stainless metal straight spline push equipment shaft coupling

We are ready to offer with sample for top quality and purpose testing.

We are ISO 9001: 2008 certified firm.

| Substance | Stainless steel, copper, brass, carbon steel, aluminum &lparaccording to customer’s requirement. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Main Products | Precision screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping parts,washer,gasket,plastic molding injection parts,standoff, CNC machining service,accessories etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Available Certificate | RoHS, SGS, Material Certification |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual,It will based on the detailed order quantity. |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Delivery of Samples | By DHL,Fedex,UPS, TNT,EMS&Hat&Hat |

| Guarantee | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | &ast You send us drawing or sample |

| &ast We carry through project assessment | |

| &ast We give you our design for your confirmation | |

| &ast We make the sample and send it to you after you confirmed our design | |

| &ast You confirm the sample then place an order and pay us 30&percnt deposit | |

| &ast We start producing | |

| &ast When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| &ast Trade is done, thank you&excl&excl | |

| Applications | Toy,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market&sol hotel equipment supplies, artware etc. |

|

US $5 / Piece | |

100 Pieces (Min. Order) |

###

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Customization: |

Available

|

|---|

###

| Material | Stainless steel, copper, brass, carbon steel, aluminum (according to customer's requirement. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Main Products | Precision screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping parts,washer,gasket,plastic molding injection parts,standoff, CNC machining service,accessories etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Available Certificate | RoHS, SGS, Material Certification |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual,It will based on the detailed order quantity. |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Delivery of Samples | By DHL,Fedex,UPS, TNT,EMS^^ |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! | |

| Applications | Toy,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market/ hotel equipment supplies, artware etc. |

|

US $5 / Piece | |

100 Pieces (Min. Order) |

###

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Customization: |

Available

|

|---|

###

| Material | Stainless steel, copper, brass, carbon steel, aluminum (according to customer's requirement. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Main Products | Precision screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping parts,washer,gasket,plastic molding injection parts,standoff, CNC machining service,accessories etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Available Certificate | RoHS, SGS, Material Certification |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual,It will based on the detailed order quantity. |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Delivery of Samples | By DHL,Fedex,UPS, TNT,EMS^^ |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! | |

| Applications | Toy,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market/ hotel equipment supplies, artware etc. |

How to Calculate Stiffness, Centering Force, Wear and Fatigue Failure of Spline Couplings

There are various types of spline couplings. These couplings have several important properties. These properties are: Stiffness, Involute splines, Misalignment, Wear and fatigue failure. To understand how these characteristics relate to spline couplings, read this article. It will give you the necessary knowledge to determine which type of coupling best suits your needs. Keeping in mind that spline couplings are usually spherical in shape, they are made of steel.

Involute splines

An effective side interference condition minimizes gear misalignment. When two splines are coupled with no spline misalignment, the maximum tensile root stress shifts to the left by five mm. A linear lead variation, which results from multiple connections along the length of the spline contact, increases the effective clearance or interference by a given percentage. This type of misalignment is undesirable for coupling high-speed equipment.

Involute splines are often used in gearboxes. These splines transmit high torque, and are better able to distribute load among multiple teeth throughout the coupling circumference. The involute profile and lead errors are related to the spacing between spline teeth and keyways. For coupling applications, industry practices use splines with 25 to fifty-percent of spline teeth engaged. This load distribution is more uniform than that of conventional single-key couplings.

To determine the optimal tooth engagement for an involved spline coupling, Xiangzhen Xue and colleagues used a computer model to simulate the stress applied to the splines. The results from this study showed that a “permissible” Ruiz parameter should be used in coupling. By predicting the amount of wear and tear on a crowned spline, the researchers could accurately predict how much damage the components will sustain during the coupling process.

There are several ways to determine the optimal pressure angle for an involute spline. Involute splines are commonly measured using a pressure angle of 30 degrees. Similar to gears, involute splines are typically tested through a measurement over pins. This involves inserting specific-sized wires between gear teeth and measuring the distance between them. This method can tell whether the gear has a proper tooth profile.

The spline system shown in Figure 1 illustrates a vibration model. This simulation allows the user to understand how involute splines are used in coupling. The vibration model shows four concentrated mass blocks that represent the prime mover, the internal spline, and the load. It is important to note that the meshing deformation function represents the forces acting on these three components.

Stiffness of coupling

The calculation of stiffness of a spline coupling involves the measurement of its tooth engagement. In the following, we analyze the stiffness of a spline coupling with various types of teeth using two different methods. Direct inversion and blockwise inversion both reduce CPU time for stiffness calculation. However, they require evaluation submatrices. Here, we discuss the differences between these two methods.

The analytical model for spline couplings is derived in the second section. In the third section, the calculation process is explained in detail. We then validate this model against the FE method. Finally, we discuss the influence of stiffness nonlinearity on the rotor dynamics. Finally, we discuss the advantages and disadvantages of each method. We present a simple yet effective method for estimating the lateral stiffness of spline couplings.

The numerical calculation of the spline coupling is based on the semi-analytical spline load distribution model. This method involves refined contact grids and updating the compliance matrix at each iteration. Hence, it consumes significant computational time. Further, it is difficult to apply this method to the dynamic analysis of a rotor. This method has its own limitations and should be used only when the spline coupling is fully investigated.

The meshing force is the force generated by a misaligned spline coupling. It is related to the spline thickness and the transmitting torque of the rotor. The meshing force is also related to the dynamic vibration displacement. The result obtained from the meshing force analysis is given in Figures 7, 8, and 9.

The analysis presented in this paper aims to investigate the stiffness of spline couplings with a misaligned spline. Although the results of previous studies were accurate, some issues remained. For example, the misalignment of the spline may cause contact damages. The aim of this article is to investigate the problems associated with misaligned spline couplings and propose an analytical approach for estimating the contact pressure in a spline connection. We also compare our results to those obtained by pure numerical approaches.

Misalignment

To determine the centering force, the effective pressure angle must be known. Using the effective pressure angle, the centering force is calculated based on the maximum axial and radial loads and updated Dudley misalignment factors. The centering force is the maximum axial force that can be transmitted by friction. Several published misalignment factors are also included in the calculation. A new method is presented in this paper that considers the cam effect in the normal force.

In this new method, the stiffness along the spline joint can be integrated to obtain a global stiffness that is applicable to torsional vibration analysis. The stiffness of bearings can also be calculated at given levels of misalignment, allowing for accurate estimation of bearing dimensions. It is advisable to check the stiffness of bearings at all times to ensure that they are properly sized and aligned.

A misalignment in a spline coupling can result in wear or even failure. This is caused by an incorrectly aligned pitch profile. This problem is often overlooked, as the teeth are in contact throughout the involute profile. This causes the load to not be evenly distributed along the contact line. Consequently, it is important to consider the effect of misalignment on the contact force on the teeth of the spline coupling.

The centre of the male spline in Figure 2 is superposed on the female spline. The alignment meshing distances are also identical. Hence, the meshing force curves will change according to the dynamic vibration displacement. It is necessary to know the parameters of a spline coupling before implementing it. In this paper, the model for misalignment is presented for spline couplings and the related parameters.

Using a self-made spline coupling test rig, the effects of misalignment on a spline coupling are studied. In contrast to the typical spline coupling, misalignment in a spline coupling causes fretting wear at a specific position on the tooth surface. This is a leading cause of failure in these types of couplings.

Wear and fatigue failure

The failure of a spline coupling due to wear and fatigue is determined by the first occurrence of tooth wear and shaft misalignment. Standard design methods do not account for wear damage and assess the fatigue life with big approximations. Experimental investigations have been conducted to assess wear and fatigue damage in spline couplings. The tests were conducted on a dedicated test rig and special device connected to a standard fatigue machine. The working parameters such as torque, misalignment angle, and axial distance have been varied in order to measure fatigue damage. Over dimensioning has also been assessed.

During fatigue and wear, mechanical sliding takes place between the external and internal splines and results in catastrophic failure. The lack of literature on the wear and fatigue of spline couplings in aero-engines may be due to the lack of data on the coupling’s application. Wear and fatigue failure in splines depends on a number of factors, including the material pair, geometry, and lubrication conditions.

The analysis of spline couplings shows that over-dimensioning is common and leads to different damages in the system. Some of the major damages are wear, fretting, corrosion, and teeth fatigue. Noise problems have also been observed in industrial settings. However, it is difficult to evaluate the contact behavior of spline couplings, and numerical simulations are often hampered by the use of specific codes and the boundary element method.

The failure of a spline gear coupling was caused by fatigue, and the fracture initiated at the bottom corner radius of the keyway. The keyway and splines had been overloaded beyond their yield strength, and significant yielding was observed in the spline gear teeth. A fracture ring of non-standard alloy steel exhibited a sharp corner radius, which was a significant stress raiser.

Several components were studied to determine their life span. These components include the spline shaft, the sealing bolt, and the graphite ring. Each of these components has its own set of design parameters. However, there are similarities in the distributions of these components. Wear and fatigue failure of spline couplings can be attributed to a combination of the three factors. A failure mode is often defined as a non-linear distribution of stresses and strains.

editor by czh 2023-01-20

China Straight Spline Drive Gear Shaft for High Quality Rice Transplanter with Good quality

Solution Description

Solution Description

Solution Parameters

| Merchandise | Spur Gear Axle Shaft |

| Content | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Personalize |

| Certification | ISO/TS16949 |

| Examination Necessity | Magnetic Powder Check, Hardness Take a look at, Dimension Take a look at |

| Color | Paint , Natural Finish ,Machining All Around |

| Materials | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Metal,Middle Steel,Steel Alloy,and many others. | |

| Stainess Steel: 303/304/316,and many others. | |

| Copper/Brass/Bronze/Pink Copper,etc. | |

| Plastic:Abdominal muscles,PP,Personal computer,Nylon,Delrin(POM),Bakelite,and so on. | |

| Size | In accordance to Customer’s drawing or samples |

| Procedure | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Slicing,etc. |

| Tolerance | ≥+/-.03mm |

| Surface Remedy | (Sandblast)&(Hard)&(Shade)Anodizing,(Chrome,Nickel,Zinc…)Plating,Portray,Powder Coating,Sharpening,Blackened,Hardened,Lasering,Engraving,and so on. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Obtainable |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane Or for every customers’ requirements. |

Our Positive aspects

Why Select US ???

1. Equipment :

Our company offers all needed generation products,

such as Hydraulic push machines, Japanese CNC lathe (TAKISAWA), Korean equipment hobbing device (I SNT), equipment shaping device, machining heart, CNC grinder, warmth therapy line etc.

2. Processing precision:

We are a professional gear & equipment shafts maker. Our gears are around 6-7 grade in mass production.

3. Firm:

We have ninety personnel, such as ten complex staffs. Covering an area of 20000 sq. meters.

four. Certification :

Oue company has handed ISO 14001 and TS16949

five.Sample support :

We supply free sample for confirmation and buyer bears the freight costs

6.OEM support :

Having our possess manufacturing unit and specialist professionals,we welcome OEM orders as well.We can style and generate the particular solution you want in accordance to your detail information

Cooperation Partner

Company Profile

Our Showcased Merchandise

|

US $1 / Piece | |

50 Pieces (Min. Order) |

###

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

|

US $1 / Piece | |

50 Pieces (Min. Order) |

###

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Stiffness and Torsional Vibration of Spline-Couplings

In this paper, we describe some basic characteristics of spline-coupling and examine its torsional vibration behavior. We also explore the effect of spline misalignment on rotor-spline coupling. These results will assist in the design of improved spline-coupling systems for various applications. The results are presented in Table 1.

Stiffness of spline-coupling

The stiffness of a spline-coupling is a function of the meshing force between the splines in a rotor-spline coupling system and the static vibration displacement. The meshing force depends on the coupling parameters such as the transmitting torque and the spline thickness. It increases nonlinearly with the spline thickness.

A simplified spline-coupling model can be used to evaluate the load distribution of splines under vibration and transient loads. The axle spline sleeve is displaced a z-direction and a resistance moment T is applied to the outer face of the sleeve. This simple model can satisfy a wide range of engineering requirements but may suffer from complex loading conditions. Its asymmetric clearance may affect its engagement behavior and stress distribution patterns.

The results of the simulations show that the maximum vibration acceleration in both Figures 10 and 22 was 3.03 g/s. This results indicate that a misalignment in the circumferential direction increases the instantaneous impact. Asymmetry in the coupling geometry is also found in the meshing. The right-side spline’s teeth mesh tightly while those on the left side are misaligned.

Considering the spline-coupling geometry, a semi-analytical model is used to compute stiffness. This model is a simplified form of a classical spline-coupling model, with submatrices defining the shape and stiffness of the joint. As the design clearance is a known value, the stiffness of a spline-coupling system can be analyzed using the same formula.

The results of the simulations also show that the spline-coupling system can be modeled using MASTA, a high-level commercial CAE tool for transmission analysis. In this case, the spline segments were modeled as a series of spline segments with variable stiffness, which was calculated based on the initial gap between spline teeth. Then, the spline segments were modelled as a series of splines of increasing stiffness, accounting for different manufacturing variations. The resulting analysis of the spline-coupling geometry is compared to those of the finite-element approach.

Despite the high stiffness of a spline-coupling system, the contact status of the contact surfaces often changes. In addition, spline coupling affects the lateral vibration and deformation of the rotor. However, stiffness nonlinearity is not well studied in splined rotors because of the lack of a fully analytical model.

Characteristics of spline-coupling

The study of spline-coupling involves a number of design factors. These include weight, materials, and performance requirements. Weight is particularly important in the aeronautics field. Weight is often an issue for design engineers because materials have varying dimensional stability, weight, and durability. Additionally, space constraints and other configuration restrictions may require the use of spline-couplings in certain applications.

The main parameters to consider for any spline-coupling design are the maximum principal stress, the maldistribution factor, and the maximum tooth-bearing stress. The magnitude of each of these parameters must be smaller than or equal to the external spline diameter, in order to provide stability. The outer diameter of the spline must be at least four inches larger than the inner diameter of the spline.

Once the physical design is validated, the spline coupling knowledge base is created. This model is pre-programmed and stores the design parameter signals, including performance and manufacturing constraints. It then compares the parameter values to the design rule signals, and constructs a geometric representation of the spline coupling. A visual model is created from the input signals, and can be manipulated by changing different parameters and specifications.

The stiffness of a spline joint is another important parameter for determining the spline-coupling stiffness. The stiffness distribution of the spline joint affects the rotor’s lateral vibration and deformation. A finite element method is a useful technique for obtaining lateral stiffness of spline joints. This method involves many mesh refinements and requires a high computational cost.

The diameter of the spline-coupling must be large enough to transmit the torque. A spline with a larger diameter may have greater torque-transmitting capacity because it has a smaller circumference. However, the larger diameter of a spline is thinner than the shaft, and the latter may be more suitable if the torque is spread over a greater number of teeth.

Spline-couplings are classified according to their tooth profile along the axial and radial directions. The radial and axial tooth profiles affect the component’s behavior and wear damage. Splines with a crowned tooth profile are prone to angular misalignment. Typically, these spline-couplings are oversized to ensure durability and safety.

Stiffness of spline-coupling in torsional vibration analysis

This article presents a general framework for the study of torsional vibration caused by the stiffness of spline-couplings in aero-engines. It is based on a previous study on spline-couplings. It is characterized by the following three factors: bending stiffness, total flexibility, and tangential stiffness. The first criterion is the equivalent diameter of external and internal splines. Both the spline-coupling stiffness and the displacement of splines are evaluated by using the derivative of the total flexibility.

The stiffness of a spline joint can vary based on the distribution of load along the spline. Variables affecting the stiffness of spline joints include the torque level, tooth indexing errors, and misalignment. To explore the effects of these variables, an analytical formula is developed. The method is applicable for various kinds of spline joints, such as splines with multiple components.

Despite the difficulty of calculating spline-coupling stiffness, it is possible to model the contact between the teeth of the shaft and the hub using an analytical approach. This approach helps in determining key magnitudes of coupling operation such as contact peak pressures, reaction moments, and angular momentum. This approach allows for accurate results for spline-couplings and is suitable for both torsional vibration and structural vibration analysis.

The stiffness of spline-coupling is commonly assumed to be rigid in dynamic models. However, various dynamic phenomena associated with spline joints must be captured in high-fidelity drivetrain models. To accomplish this, a general analytical stiffness formulation is proposed based on a semi-analytical spline load distribution model. The resulting stiffness matrix contains radial and tilting stiffness values as well as torsional stiffness. The analysis is further simplified with the blockwise inversion method.

It is essential to consider the torsional vibration of a power transmission system before selecting the coupling. An accurate analysis of torsional vibration is crucial for coupling safety. This article also discusses case studies of spline shaft wear and torsionally-induced failures. The discussion will conclude with the development of a robust and efficient method to simulate these problems in real-life scenarios.

Effect of spline misalignment on rotor-spline coupling

In this study, the effect of spline misalignment in rotor-spline coupling is investigated. The stability boundary and mechanism of rotor instability are analyzed. We find that the meshing force of a misaligned spline coupling increases nonlinearly with spline thickness. The results demonstrate that the misalignment is responsible for the instability of the rotor-spline coupling system.

An intentional spline misalignment is introduced to achieve an interference fit and zero backlash condition. This leads to uneven load distribution among the spline teeth. A further spline misalignment of 50um can result in rotor-spline coupling failure. The maximum tensile root stress shifted to the left under this condition.

Positive spline misalignment increases the gear mesh misalignment. Conversely, negative spline misalignment has no effect. The right-handed spline misalignment is opposite to the helix hand. The high contact area is moved from the center to the left side. In both cases, gear mesh is misaligned due to deflection and tilting of the gear under load.

This variation of the tooth surface is measured as the change in clearance in the transverse plain. The radial and axial clearance values are the same, while the difference between the two is less. In addition to the frictional force, the axial clearance of the splines is the same, which increases the gear mesh misalignment. Hence, the same procedure can be used to determine the frictional force of a rotor-spline coupling.

Gear mesh misalignment influences spline-rotor coupling performance. This misalignment changes the distribution of the gear mesh and alters contact and bending stresses. Therefore, it is essential to understand the effects of misalignment in spline couplings. Using a simplified system of helical gear pair, Hong et al. examined the load distribution along the tooth interface of the spline. This misalignment caused the flank contact pattern to change. The misaligned teeth exhibited deflection under load and developed a tilting moment on the gear.

The effect of spline misalignment in rotor-spline couplings is minimized by using a mechanism that reduces backlash. The mechanism comprises cooperably splined male and female members. One member is formed by two coaxially aligned splined segments with end surfaces shaped to engage in sliding relationship. The connecting device applies axial loads to these segments, causing them to rotate relative to one another.

editor by czh 2022-12-31

China Wholesale Transplanter Straight Spline Drive Gear Shaft with ce certificate top quality Good price

Item Description

Product Description

Product Parameters

| Merchandise | Spur Gear Axle Shaft |

| Materials | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customise |

| Certification | ISO/TS16949 |

| Check Requirement | Magnetic Powder Test, Hardness Take a look at, Dimension Take a look at |

| Color | Paint , Natural Finish ,Machining All Close to |

| Substance | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Metal: Carbon Steel,Middle Steel,Steel Alloy,and so on. | |

| Stainess Steel: 303/304/316,and so on. | |

| Copper/Brass/Bronze/Crimson Copper,and so forth. | |

| Plastic:Ab muscles,PP,Laptop,Nylon,Delrin(POM),Bakelite,and so on. | |

| Measurement | In accordance to CZPT er’s drawing or samples |

| Procedure | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Reducing,and many others. |

| Tolerance | ≥+/-.03mm |

| Surface area Treatment method | (Sandblast)&(Difficult)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,and so forth. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Obtainable |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane Or for every CZPT ers’ requirements. |

Our Benefits

Why Pick US ???

1. Equipment :

Our company offers all necessary production equipment,

including CZPT ulic press devices, Japanese CNC lathe (TAKISAWA), Korean equipment hobbing device (I SNT), gear shaping machine, machining center, CNC grinder, heat remedy line etc.

2. Processing precision:

We are a professional gear & gear shafts maker. Our gears are all around 6-7 quality in mass manufacturing.

three. Firm:

We have ninety employees, which includes ten complex staffs. Covering an location of 20000 sq. meters.

four. Certification :

Oue company has handed ISO 14001 and TS16949

5.Sample provider :

We supply free of charge sample for confirmation and CZPT er bears the freight fees

six.OEM service :

Obtaining CZPT possess manufacturing facility and expert specialists,we welcome CZPT orders as effectively.We can design and style and generate the particular merchandise you need according to your element details

Cooperation Companion

Organization Profile

Our Featured Items

EP delivers a wide assortment of stock PTO shafts and yokes, clutches, shaft handles, pipes and any other accessories to fulfill your PTO demands. Electricity get-offs are used to transfer power from a tractor or other electricity resource to a device. The two most generally employed tractor electricity take-offs are 540 and one thousand rpm, and energy just take-offs can be of distinct dimensions and lengths. If you have any inquiries about cardan shafts, cardan shaft areas, dimension drawings or extensions, you should speak to our experts on-line.

China Long Stainless Steel Straight Spline Spline Drive Gear Shaft for Rice Transplanter with ce certificate top quality Good price

Merchandise Description

Sample services

We supply free of charge sample for confirmation and CZPT er bears the freight costs

OEM support

Getting CZPT very own manufacturing unit and expert experts,we welcome CZPT orders as effectively.We can design and make the specific merchandise you require according to your depth details

Right after-sale Service

Our enthusiastic and welcoming CZPT er services representatives are completely ready to help with any concerns or problems

| Product | Spur Gear Axle Shaft |

| Content | 4140,4340,40Cr,42Crmo,42Crmo4 |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Take a look at Prerequisite | Magnetic Powder Check, Hardness Examination, Dimension Examination |

| Shade | Paint , CZPT Finish ,Machining All Close to |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Metal Alloy,and so on. | |

| Stainess Metal: 303/304/316,and many others. | |

| Copper/Brass/Bronze/Pink Copper,and many others. | |

| Plastic:Ab muscles,PP,Laptop,Nylon,Delrin(POM),Bakelite,etc. | |

| Dimension | According to CZPT er’s drawing or samples |

| Method | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Slicing,and so on. |

| Tolerance | ≥+/-.03mm |

| Surface area Treatment method | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Portray,Powder Coating,Sprucing,Blackened,Hardened,Lasering,Engraving,and so forth. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Offered |

| Packing | Spline shield protect ,Wood box ,Watertight membrane Or per CZPT ers’ requirements. |

The tractor’s short shaft, frequently referred to as the PTO, transmits electricity from the tractor to the PTO-pushed machine or tool. Electrical power transfer is accomplished by connecting the machine’s driveshaft to the tractor’s PTO stub shaft. The PTO and driveshaft have been operate at 540 rpm (9 cycles/sec) or a thousand rpm (sixteen.6 cycles/sec). At any speed, their rotation is proportional to the pace of the tractor motor. Most incidents involving PTO stubs are thanks to clothing being caught by a hectic but unsuspecting PTO stub. Motives a PTO stub may possibly continue to be engaged contain: the operator forgets or does not know the PTO clutch is engaged sees the PTO stub spinning but thinks it is not unsafe ample to release it, or the operator is engaged in perform routines. Shoelaces, pant legs, overalls and coveralls, sweatshirts, and trench coats are clothes that can be grabbed and wrapped all around spinning PTO spools.

China Long Stainless Steel Straight Spline Worm Drive Gear Shaft for Rice Transplanter with ce certificate top quality Good price

Item Description

Sample services

We supply free of charge sample for confirmation and CZPT er bears the freight fees

OEM services

Possessing CZPT possess manufacturing facility and specialist professionals,we welcome CZPT orders as well.We can design and style and create the distinct item you need in accordance to your depth information

Following-sale Provider

Our enthusiastic and welcoming CZPT er service associates are completely ready to support with any queries or troubles

| Product | Spur Gear Axle Shaft |

| Materials | 4140,4340,40Cr,42Crmo,42Crmo4 |

| OEM NO | Customise |

| Certification | ISO/TS16949 |

| Take a look at Necessity | Magnetic Powder Take a look at, Hardness Test, Dimension Test |

| Colour | Paint , CZPT Complete ,Machining All Close to |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Metal: Carbon Steel,Middle Metal,Steel Alloy,and so forth. | |

| Stainess Steel: 303/304/316,and so on. | |

| Copper/Brass/Bronze/Crimson Copper,etc. | |

| Plastic:Abs,PP,Computer,Nylon,Delrin(POM),Bakelite,and so on. | |

| Measurement | In accordance to CZPT er’s drawing or samples |

| Approach | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Chopping,etc. |

| Tolerance | ≥+/-.03mm |

| Surface Therapy | (Sandblast)&(Hard)&(Shade)Anodizing,(Chrome,Nickel,Zinc…)Plating,Portray,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Accessible |

| Packing | Spline protect protect ,Wooden box ,Watertight membrane Or per CZPT ers’ requirements. |